Polymethylhydrosiloxane

- CAS NO.:9004-73-3

- Empirical Formula: C5H11OSi*

- Molecular Weight: 115.22574

- MDL number: MFCD00084478

- SAFETY DATA SHEET (SDS)

- Update Date: 2024-11-20 17:10:30

What is Polymethylhydrosiloxane?

Description

Methylpolysilicones (also called dimethylpolysiloxanes) are

high-molecular weight organic compounds of silicon which are

similar in chemical structure to inorganic silicates. They are members

of a large family in which silicon and oxygen atoms form a

siloxy skeleton to which various alkyl and aryl groups are attached

in regular, repetitive fashion. The methylpolysilicones may be

characterized by the following formula:

Si(CH3)3O[Si(CH3)2O] nSi(CH3)3

where "n" can be varied from 0 to 10,000 or higher.

The commercial methylpolysilicones are usually linear polymers,

although cyclic forms may also be utilized.

Methylpolysilicones can be prepared in viscosity grades ranging

from one to several hundred thousand centistokes (cs) depending

on the degree of polymerization. Those employed in food uses

generally have "n" values of 200-400, with molecular weights

usually between 14,000 and 21,000. In this molecular weight

range, methylpolysilicones are clear, colorless, viscous liquids,

which may contain up to 5% silicon dioxide. With higher degrees

of polymerization, resins and rubbers are produced. The methylpolysilicones

are insoluble in water and the lower alcohols, but

soluble in most aliphatic and aromatic hydrocarbon solvents. The

polymers are nonionic, inert compounds strongly resistant to

chemical and thermal attack. They are hydrophobic, greasy, and

markedly antiadhesive.

silica gel as well as emulsifying agents and preservatives. Foodgrade

methylpolysilicones must meet the following specifications:

Refractive index: 1.400 to 1.404.

Specific gravity: 0.964 to 0.973.

Viscosity: 300 to 600 cs.

Loss on heating: Not more than 18%.

Limit of impurities: Arsenic, not more than 3 parts per million

(ppm); heavy metals, not more than 10 ppm (expressed as lead).

The antifoaming and hydrophobic properties of dimethylpolysilicones

are also utilized medically in patients suffering from

excessive gas production or retention such as flatulence, gastric

bloating, or postoperative gaseous distention. They have also been

used to reduce gas shadows in radiography of the bowel and to

improve visualization in gastroscopy. The usual therapeutic adult

dose is 150-400 mg daily. Silicones are also employed to prevent

dermal irritation in bedridden patients. Medical grade preparations

(simethicone) must contain 93-99% dimethylpolysilicone, not

more than 4.5% silicon dioxide, and have a viscosity not less than

300 cs.

Because of their chemical and thermal resistance together with

their antiadhesive and hydrophobic properties, methylpolysilicones

have found various uses in the food industry. They are used

to coat containers and molds for bakery products, candies, and

confections; to impregnate packaging and wrapping paper which

contact foods; and to reduce foaming in various fermentation and

canning processes. Methylpolysilicones at low concentrations

(0.03-0.05 ppm) reduce thermal and oxidative deterioration of frying

fat by forming a protective film at the oil-air interface. At

higher levels (1-10 ppm), silicones added to shortening and other

frying fats may eliminate smoking difficulties by raising the smoke

point 20-30°F. Silicones have also been incorporated into cellulosic

sausage casings to facilitate the casing removal from the

enclosed meat mass.

Chemical properties

clear colorless viscous liquid

Physical properties

colorless free flowing liquid; average molecular weight 1500-2200 g mol?1 (supplier dependent); effective mass per hydride of 60 g mol?1; d = 1.006.

The Uses of Polymethylhydrosiloxane

Polymethylhydrosiloxane (PMHS) is an easily handled, inexpensive, non-toxic, and mild reducing agent. Although relatively inert towards organic functionality, PMHS can transfer its hydride to a variety of metal catalysts (including Sn, Ti, Zn, Cu, and Pd) which can then participate in a wide range of reductions. Alternatively, when made hypercoordinate by the action of fluoride or other nucleophiles, PMHS can act directly as a reducing agent. Polymethylhydrosiloxane is widely used as reducing agent often used in conjunction with metal catalysts or nucleophilic activators.

The Uses of Polymethylhydrosiloxane

methicone is a type of silicone used primarily in the formulation of free-flowing cosmetic powders. Methicone can also be found in cosmetic preparations as a skin surface sealant to reduce transepidermal water loss.

Preparation

hydrolysis of methyldichlorosilane followed by heating (60–150 °C) the resultant mixture of cyclic silanes in the presence of hexamethyldisiloxane generates the linear polysiloxane.

Properties of Polymethylhydrosiloxane

| Boiling point: | >177 °C(lit.) |

| Density | 1.006 g/mL at 25 °C(lit.) |

| refractive index | n |

| Flash point: | 250 °F |

| solubility | most ethereal, chlorinated, or hydrocarbon solvents as

well as EtOH, i-PrOH, warm DMF, and warm NMP; insoluble

in MeOH, DMSO, acetonitrile, and water. |

| form | Viscous Liquid |

| color | Clear colorless |

| Water Solubility | PRACTICALLY INSOLUBLE |

| Sensitive | Moisture Sensitive |

| CAS DataBase Reference | 9004-73-3(CAS DataBase Reference) |

| EPA Substance Registry System | Poly[oxy(methylsilylene)] (9004-73-3) |

Safety information for Polymethylhydrosiloxane

Computed Descriptors for Polymethylhydrosiloxane

Abamectin manufacturer

New Products

4-AMINO-TETRAHYDRO-PYRAN-4-CARBOXYLIC ACID HCL 4-(Dimethylamino)tetrahydro-2H-pyran-4-carbonitrile 4-Aminotetrahydropyran-4-carbonitrile Hydrochloride (R)-3-Aminobutanenitrile Hydrochloride 3-((Dimethylamino)methyl)-5-methylhexan-2-one oxalate 1,4-Dioxa-8-azaspiro[4.5]decane 5-Bromo-2-nitropyridine Nimesulide BP Aceclofenac IP/BP/EP Diclofenac Sodium IP/BP/EP/USP Mefenamic Acid IP/BP/EP/USP Ornidazole IP Diclofenac Potassium THOMAIND PAPER PH 2.0 TO 4.5 1 BOX BUFFER CAPSULE PH 9.2 - 10 CAP SODIUM CHLORIDE 0.1N CVS ALLOXAN MONOHYDRATE 98% PLATINUM 0.5% ON 3 MM ALUMINA PELLETS (TYPE 73) LITHIUM AAS SOLUTION 2-Bromo-1-(bromomethyl)-3-chloro-5-nitrobenzene 2-Bromo-3-nitroaniline N-(3-Hydroxypropyl)-N-methylacetamide 3-Bromo-6-chloropyridazine 4-ethyl-3-nitrobenzoic acidRelated products of tetrahydrofuran

You may like

-

Polymethylhydrosiloxane CAS 9004-73-3View Details

Polymethylhydrosiloxane CAS 9004-73-3View Details

9004-73-3 -

Polymethylhydrosiloxane CAS 9004-73-3View Details

Polymethylhydrosiloxane CAS 9004-73-3View Details

9004-73-3 -

1823368-42-8 98%View Details

1823368-42-8 98%View Details

1823368-42-8 -

2-(3-(tert-butyl)phenoxy)-2-methylpropanoic acid 1307449-08-6 98%View Details

2-(3-(tert-butyl)phenoxy)-2-methylpropanoic acid 1307449-08-6 98%View Details

1307449-08-6 -

Ethyl 3-(furan-2-yl)-3-hydroxypropanoate 25408-95-1 98%View Details

Ethyl 3-(furan-2-yl)-3-hydroxypropanoate 25408-95-1 98%View Details

25408-95-1 -

2-Chloro-5-fluoro-1-methoxy-3-methylbenzene 98%View Details

2-Chloro-5-fluoro-1-methoxy-3-methylbenzene 98%View Details

1805639-70-6 -

1784294-80-9 98%View Details

1784294-80-9 98%View Details

1784294-80-9 -

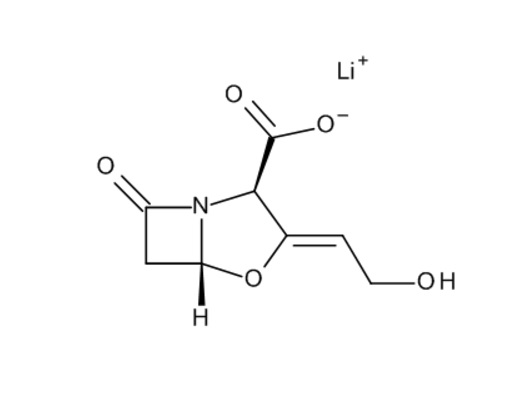

Lithium ClavulanateView Details

Lithium ClavulanateView Details

61177-44-4