POLYBUTADIENE DIACRYLATE

- CAS NO.:9003-17-2

- Empirical Formula: C4H6

- Molecular Weight: 54.09044

- MDL number: MFCD00803864

- SAFETY DATA SHEET (SDS)

- Update Date: 2024-07-02 17:04:22

What is POLYBUTADIENE DIACRYLATE?

Chemical properties

low molecular weight formulations are liquid, Polybutadiene is a homopolymer of butadiene. The catalysts involved in the polymerization process determine the structure and molecular weight of the rubber. It is used in tires and for other products that require abrasion resistance. At times both SBR and polybutadiene are extended with oils. There are underlying hazards associated with the individual oils, some of which are carcinogenic in animals and suspected human carcinogens.

The Uses of POLYBUTADIENE DIACRYLATE

Component of water soluble binders and electrical encapsulants.

The Uses of POLYBUTADIENE DIACRYLATE

Co-reactant for air curing coatings.

The Uses of POLYBUTADIENE DIACRYLATE

PB-cis can be polymerized with styrene for the formation of high impact polystyrene (HIPS). It may also be used as a toughening agent for acrylonitrile butadiene rubber (ABS) based resins.

Definition

ChEBI: A macromolecule composed of repeating but-2-ene-1,4-diyl units.

Production Methods

The production of polybutadiene involves copolymerizing three parts butadiene and one part styrene. Also present in small amounts is an initiator or catalyst, which is usually a peroxide, and a chain-modifying agent such as dodecyl mercaptan. Isotactic cis-1,4 polybutadiene has been synthesized using a titanium halide such as titanium tetrachloride or titanium tetrabromide; using a cobalt salt of octanoate or napthenate, or complexes with pyridine; or using nickel halide catalyst based on boron trifluoride reduced by aluminum alkyls.

General Description

Polybutadiene is a synthetic rubber that is produced by solution polymerization of 1,3-butadiene. It has excellent mechanical properties which include low temperature flexibility and abrasion resistance. It can be cured by using sulfur based donors and peroxides to result in a highly cross-linked polymer with high resilience.

Carcinogenicity

The individual oil extenders are classified as suspected human carcinogens.

Properties of POLYBUTADIENE DIACRYLATE

| Melting point: | −6 °C |

| Density | 0.9 g/mL at 25 °C (lit.) |

| refractive index | n |

| Flash point: | 113 °C |

| storage temp. | Store at R.T. |

| solubility | aliphatic hydrocarbons: soluble |

| form | Slab |

| color | Clear |

| Stability: | Stable. Incompatible with strong oxidizing agents. |

| EPA Substance Registry System | Polybutadiene (9003-17-2) |

Safety information for POLYBUTADIENE DIACRYLATE

Computed Descriptors for POLYBUTADIENE DIACRYLATE

Abamectin manufacturer

New Products

4-AMINO-TETRAHYDRO-PYRAN-4-CARBOXYLIC ACID HCL 4-(Dimethylamino)tetrahydro-2H-pyran-4-carbonitrile 4-Aminotetrahydropyran-4-carbonitrile Hydrochloride (R)-3-Aminobutanenitrile Hydrochloride 3-((Dimethylamino)methyl)-5-methylhexan-2-one oxalate 1,4-Dioxa-8-azaspiro[4.5]decane 5-Bromo-2-nitropyridine Nimesulide BP Aceclofenac IP/BP/EP Diclofenac Sodium IP/BP/EP/USP Mefenamic Acid IP/BP/EP/USP Ornidazole IP Diclofenac Potassium THOMAIND PAPER PH 2.0 TO 4.5 1 BOX BUFFER CAPSULE PH 9.2 - 10 CAP SODIUM CHLORIDE 0.1N CVS ALLOXAN MONOHYDRATE 98% PLATINUM 0.5% ON 3 MM ALUMINA PELLETS (TYPE 73) LITHIUM AAS SOLUTION 2-Bromo-1-(bromomethyl)-3-chloro-5-nitrobenzene 2-Bromo-3-nitroaniline N-(3-Hydroxypropyl)-N-methylacetamide 3-Bromo-6-chloropyridazine 4-ethyl-3-nitrobenzoic acidRelated products of tetrahydrofuran

You may like

-

9003-17-2 1,3-Polybutadiene 99%View Details

9003-17-2 1,3-Polybutadiene 99%View Details

9003-17-2 -

Polybutadiene, cis CAS 9003-17-2View Details

Polybutadiene, cis CAS 9003-17-2View Details

9003-17-2 -

Polybutadiene, predominantly 1,2-addition CAS 9003-17-2View Details

Polybutadiene, predominantly 1,2-addition CAS 9003-17-2View Details

9003-17-2 -

Polybutadiene CAS 9003-17-2View Details

Polybutadiene CAS 9003-17-2View Details

9003-17-2 -

1823368-42-8 98%View Details

1823368-42-8 98%View Details

1823368-42-8 -

2-(3-(tert-butyl)phenoxy)-2-methylpropanoic acid 1307449-08-6 98%View Details

2-(3-(tert-butyl)phenoxy)-2-methylpropanoic acid 1307449-08-6 98%View Details

1307449-08-6 -

Ethyl 3-(furan-2-yl)-3-hydroxypropanoate 25408-95-1 98%View Details

Ethyl 3-(furan-2-yl)-3-hydroxypropanoate 25408-95-1 98%View Details

25408-95-1 -

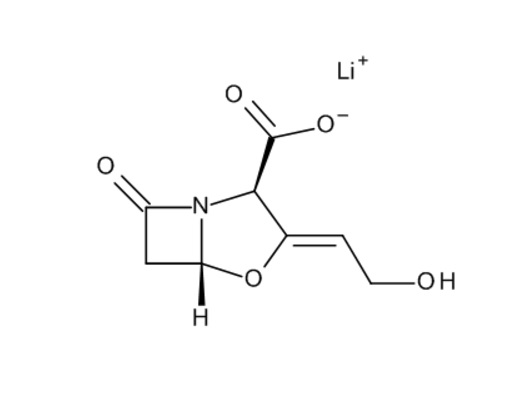

Lithium ClavulanateView Details

Lithium ClavulanateView Details

61177-44-4