Evogliptin

- CAS NO.:1222102-29-5

- Empirical Formula: C19H26F3N3O3

- Molecular Weight: 401.42

- MDL number: MFCD28502041

- SAFETY DATA SHEET (SDS)

- Update Date: 2024-10-28 23:16:16

What is Evogliptin?

Description

Developed by Dong-A ST, evogliptin was approved in 2015 in the Republic of Korea for blood glucose control in patients with diabetes mellitus type 2 (type 2 DM). Evogliptin is an orally bioavailable dipeptidyl peptidase IV (DPP-4) inhibitor, which acts to prevent insulin secretion following meals. Dong-A ST arranged licensing agreements with Geropharm and Eurofarma Laboratórios for the sale of evogliptin in various countries in eastern Europe and Brazil, respectively, pending future approvals. While a manufacturing route has not been disclosed to date, the most scalable published route is described below.

The Uses of Evogliptin

ent-Evogliptin L-tartrate Salt is enantiomer of Evogliptin (CAS 1222102-29-5) parent compound, which is a dipeptidyl peptidase-4 (DPP-4) inhibitor for the treatment of type 2 diabetes.

Synthesis

The synthesis of piperizone 125 began from commercially

available amino acid derivative 127 . The alcohol

within 125 was then quantitatively converted to tert-butyl ether

128 by treatment with isobutylene gas in the presence of acid.

Subsequent hydrogenation to remove the Cbz protecting group

resulted in amine 129, and this was followed by reductive

amination to provide ethylene diamine intermediate 130.

Hydrogenative carbamate removal facilitated a cyclization

reaction, giving rise to piperizone 131 as the free base. Finally,

treatment with a tartaric acid derivative delivered the stable

piperizone salt 125.

The second key synthon of evogliptin is the |?-amino acid

fragment 136.

Commercially available acid 132 was treated with CDI prior to

subjection to Meldrum?ˉs acid to afford ketodiester 133.

Subjection of 133 to warm EtOH triggered a decarboxylation

event, and this was followed by reductive amination reaction

involving ammonium acetate and the remaining ketone

functionality to afford racemic amine 134 in 91% over the

three steps. Resolution with a tartaric acid derivative followed

by free base formation with sodium carbonate gave the

enantiopure aminoester 135 in good yield. Finally, a two-step

Boc protection followed by ester saponification furnished

aminoester 136 in 89% yield over the final two-step sequence,

setting the stage for the final assembly of evogliptin.

The final API was assembled in a straightforward manner

from intermediates 125 and 136. Acid 136 was

first activated as the mixed anhydride, followed by the addition

of 125 in the presence of Hünig?ˉs base to give penultimate

product 137 in 71% over two steps. Hydrogenolytic removal of the benzyl carbamate afforded evogliptin (XVI), with a longest

linear sequence of eight steps from simple amino acid building

blocks.

Properties of Evogliptin

| Boiling point: | 571.5±50.0 °C(Predicted) |

| Density | 1.234±0.06 g/cm3(Predicted) |

| pka | 14.09±0.40(Predicted) |

Safety information for Evogliptin

Computed Descriptors for Evogliptin

Abamectin manufacturer

New Products

4-AMINO-TETRAHYDRO-PYRAN-4-CARBOXYLIC ACID HCL 4-(Dimethylamino)tetrahydro-2H-pyran-4-carbonitrile 4-Aminotetrahydropyran-4-carbonitrile Hydrochloride (R)-3-Aminobutanenitrile Hydrochloride 3-((Dimethylamino)methyl)-5-methylhexan-2-one oxalate 1,4-Dioxa-8-azaspiro[4.5]decane 5-Bromo-2-nitropyridine Nimesulide BP Aceclofenac IP/BP/EP Diclofenac Sodium IP/BP/EP/USP Mefenamic Acid IP/BP/EP/USP Ornidazole IP Diclofenac Potassium THOMAIND PAPER PH 2.0 TO 4.5 1 BOX BUFFER CAPSULE PH 9.2 - 10 CAP SODIUM CHLORIDE 0.1N CVS ALLOXAN MONOHYDRATE 98% PLATINUM 0.5% ON 3 MM ALUMINA PELLETS (TYPE 73) LITHIUM AAS SOLUTION 2-Bromo-1-(bromomethyl)-3-chloro-5-nitrobenzene 2-Bromo-3-nitroaniline N-(3-Hydroxypropyl)-N-methylacetamide 3-Bromo-6-chloropyridazine 4-ethyl-3-nitrobenzoic acidYou may like

-

Evogliptin 98%View Details

Evogliptin 98%View Details -

1-Methyl-6-oxo-1,6-dihydropyridazine-3-carbonitrile 98%View Details

1-Methyl-6-oxo-1,6-dihydropyridazine-3-carbonitrile 98%View Details

99903-60-3 -

1823368-42-8 98%View Details

1823368-42-8 98%View Details

1823368-42-8 -

2-(3-(tert-butyl)phenoxy)-2-methylpropanoic acid 1307449-08-6 98%View Details

2-(3-(tert-butyl)phenoxy)-2-methylpropanoic acid 1307449-08-6 98%View Details

1307449-08-6 -

Ethyl 3-(furan-2-yl)-3-hydroxypropanoate 25408-95-1 98%View Details

Ethyl 3-(furan-2-yl)-3-hydroxypropanoate 25408-95-1 98%View Details

25408-95-1 -

2-Chloro-5-fluoro-1-methoxy-3-methylbenzene 98%View Details

2-Chloro-5-fluoro-1-methoxy-3-methylbenzene 98%View Details

1805639-70-6 -

1784294-80-9 98%View Details

1784294-80-9 98%View Details

1784294-80-9 -

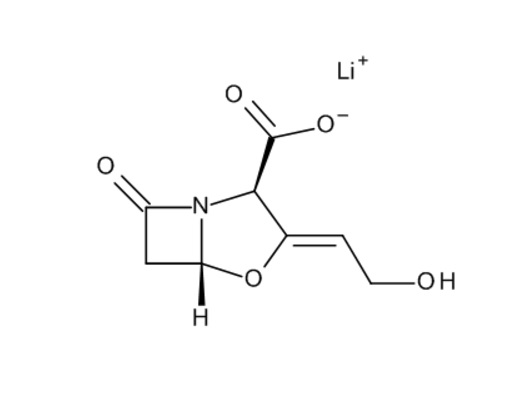

Lithium ClavulanateView Details

Lithium ClavulanateView Details

61177-44-4