ChlorinatedPolyvinylChloride

- CAS NO.:68648-82-8

- Molecular Weight: 0

- Update Date: 2023-04-23 13:52:06

What is ChlorinatedPolyvinylChloride?

Chemical properties

light-coloured solid; commercial product

Preparation

Depending on the conditions used, various products may be obtained by the

post-chlorination of poly(vinyl chloride). Two types of product are made commercially, one by chlorination at low temperature and one by chlorination at high temperature.

(i) Low temperature chlorination. In one process, an aqueous dispersion of

poly(vinyl chloride) (containing a swelling agent such as chloroform) is heated

to about 50??C, illuminated and treated with chlorine. Under these conditions,

substitution occurs mainly at the unsubstituted methylene groups so that s-dichloroethylene units are formed. Commercial chlorinated poly(vinyl chloride) has a chlorine content of about 63-68% and is thus, in effect, a copolymer

of vinyl chloride and s-dichloroethylene (poly-s-dichloroethylene would have

73% CI):

The properties of chlorinated poly(vinyl chloride) of this type are in the main similar to those of unplasticized poly(vinyl chloride). The most significant result of chlorination is the elevation of softening point, as a result of which the maximum service temperature is about 100??C compared to about 65??C for unplasticized poly(vinyl chloride). Chlorination also leads to a deterioration in heat stability and an increase in melt viscosity and thus chlorinated poly(vinyl chloride) is rather more difficult to process; nevertheless, the material can be satisfactorily extruded and injection moulded. The major application for chlorinated poly(vinyl chloride) is in plumbing applications, particularly hot and cold water distribution and hot, corrosive effluent handling.

(ii) High temperature chlorination. In this case, chlorination is conducted in solution at about 100??C. A suitable solvent for the poly(vinyl chloride) is tetrachloroethane. Under these conditions, substitution occurs extensively at the -CH2- group and there is also chain scission. The most significant effect of this type of chlorination is that the product is soluble in low cost solvents such as acetone, butyl acetate and methylene chloride. Such solutions find application in adhesives and protective coatings; they are also used for spinning fibre which, because of its resistance to corrosive liquids, is utilized mainly for chemical filter cloth. Poly(vinyl chloride) chlorinated in this manner has a low softening point, low impact strength and poor colour stability and is not used for the production of articles by conventional moulding operations.

Properties and Applications

Polyvinyl chloride can be modified through chlorination to obtain a vinyl chloride plastic with improved corrosion resistance and the ability to withstand operating temperatures that are 20–30°C higher. Hence, CPVC, which has about the same range of chemical resistance as rigid PVC, is extensively used as piping, fittings, ducts, tanks, and pumps for handling highly corrosive liquids and for hot water. For instance, it has been determined that the chemical resistance is satisfactory for CPVC in comparison with PVC on exposure for 30 days in such environments as 20wt.% acetic acid, 40–50 wt.% chromic acid, 60 to 70 wt.% nitric acid, at 30°C and 80 wt.% sulfuric acid, hexane, at 50°C and 80 wt.% sodium hydroxide until 80°C.

Properties of ChlorinatedPolyvinylChloride

| Stability: | Stable. |

| CAS DataBase Reference | 68648-82-8 |

| EPA Substance Registry System | Ethene, chloro-, homopolymer, chlorinated (68648-82-8) |

Safety information for ChlorinatedPolyvinylChloride

Computed Descriptors for ChlorinatedPolyvinylChloride

Abamectin manufacturer

New Products

4-AMINO-TETRAHYDRO-PYRAN-4-CARBOXYLIC ACID HCL 4-(Dimethylamino)tetrahydro-2H-pyran-4-carbonitrile 4-Aminotetrahydropyran-4-carbonitrile Hydrochloride (R)-3-Aminobutanenitrile Hydrochloride 3-((Dimethylamino)methyl)-5-methylhexan-2-one oxalate 1,4-Dioxa-8-azaspiro[4.5]decane 5-Bromo-2-nitropyridine Nimesulide BP Aceclofenac IP/BP/EP Mefenamic Acid IP/BP/EP/USP Diclofenac Sodium IP/BP/EP/USP Ornidazole IP Diclofenac Potassium THOMAIND PAPER PH 2.0 TO 4.5 1 BOX BUFFER CAPSULE PH 9.2 - 10 CAP SODIUM CHLORIDE 0.1N CVS ALLOXAN MONOHYDRATE 98% PLATINUM 0.5% ON 3 MM ALUMINA PELLETS (TYPE 73) LITHIUM AAS SOLUTION 2-Bromo-1-(bromomethyl)-3-chloro-5-nitrobenzene 2-Bromo-3-nitroaniline N-(3-Hydroxypropyl)-N-methylacetamide 3-Bromo-6-chloropyridazine 4-ethyl-3-nitrobenzoic acidYou may like

-

1-Methyl-6-oxo-1,6-dihydropyridazine-3-carbonitrile 98%View Details

1-Methyl-6-oxo-1,6-dihydropyridazine-3-carbonitrile 98%View Details

99903-60-3 -

88491-46-7 98%View Details

88491-46-7 98%View Details

88491-46-7 -

1823368-42-8 98%View Details

1823368-42-8 98%View Details

1823368-42-8 -

2-(3-(tert-butyl)phenoxy)-2-methylpropanoic acid 1307449-08-6 98%View Details

2-(3-(tert-butyl)phenoxy)-2-methylpropanoic acid 1307449-08-6 98%View Details

1307449-08-6 -

Ethyl 3-(furan-2-yl)-3-hydroxypropanoate 25408-95-1 98%View Details

Ethyl 3-(furan-2-yl)-3-hydroxypropanoate 25408-95-1 98%View Details

25408-95-1 -

2-Chloro-5-fluoro-1-methoxy-3-methylbenzene 98%View Details

2-Chloro-5-fluoro-1-methoxy-3-methylbenzene 98%View Details

1805639-70-6 -

1784294-80-9 98%View Details

1784294-80-9 98%View Details

1784294-80-9 -

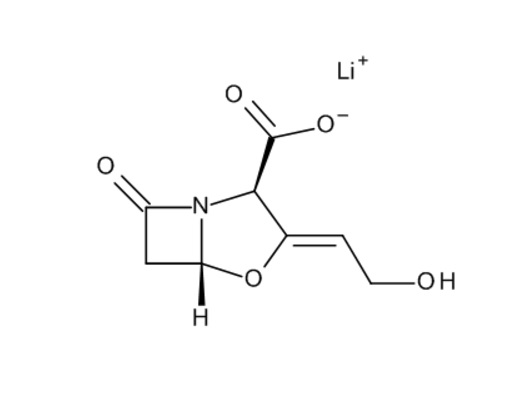

Lithium ClavulanateView Details

Lithium ClavulanateView Details

61177-44-4